믿 을 만 한 PCB 회로 제조 업 체!! Contact Us

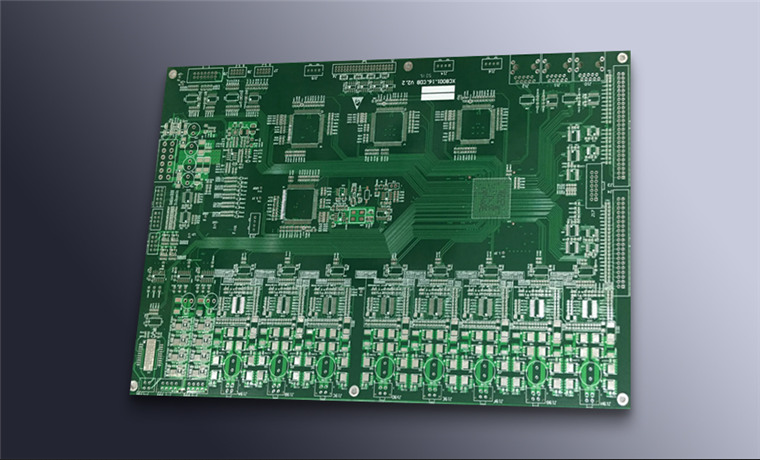

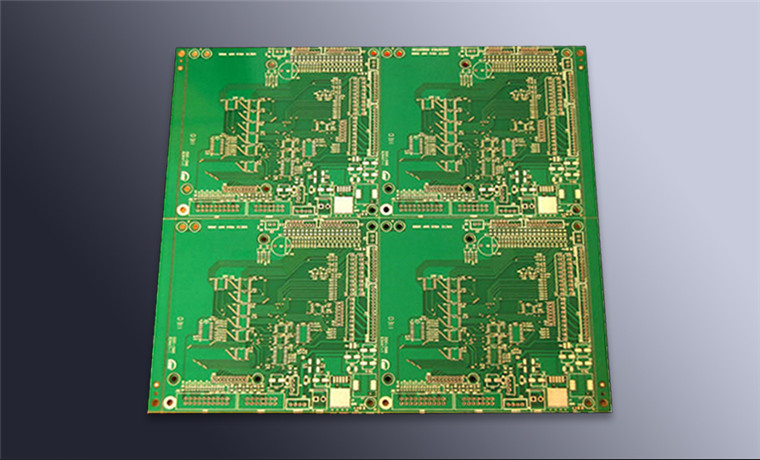

PCB의 전자 제품의 소형화 및 박형화의 발전 추세에 따라 전자 제품의 많은 회로 기판은 SMT 제조 기술, 즉 표면 실장 기술, 즉 모든 전자 부품이 회로 기판의 표면과 결합되어 필요하지 않습니다. 이전과 같이 되도록. 기판에 남겨둔 구멍에 끼우고 뒷면부터 납땜합니다.

이 제품의 전기면도 제품의 전면에 해당하는 제품의 특징에도 불구하고 이에 대한 자세한 내용은 전면 전면 전면에 나와 있습니다. 이전과 현재 , 뺑뺑이 뺑뺑이 돌고 있습니다.

프린트 기판의 브라켓은 고온에 강한 재질로 되어 있습니다. PCB 보드로 전체 생산 공정을 로드합니다. 그런 다음 부품이 있는 PCB 보드는 조립 라인의 끝에서 직원에 의해 제거됩니다. 빈 지지 보드는 라인의 끝으로 반환되고 PCB가 다시 채워집니다.

PCB 트레이를 로드하고 생산 라인으로 흘러갈 때까지 기다립니다.

생산 라인의 첫 번째 전투는 이러한 PCB 보드에 주석을 적용하는 것입니다. 즉, 이러한 보드의 상단을 스텐실로 덮고 스텐실에 구멍이 있습니다. 이 구멍은 구성 요소를 설치해야 하는 PCB 기판, 즉 솔더 조인트와 마주합니다. , 부품 용접을 위한 솔더 조인트 및 PCB, 기계 및 전체 스틸 메쉬에 의해 제어되는 와이퍼. 이 때 PCB의 솔더 조인트 위치는 솔더 페이스트를 강철 메쉬의 두께로 덮습니다.