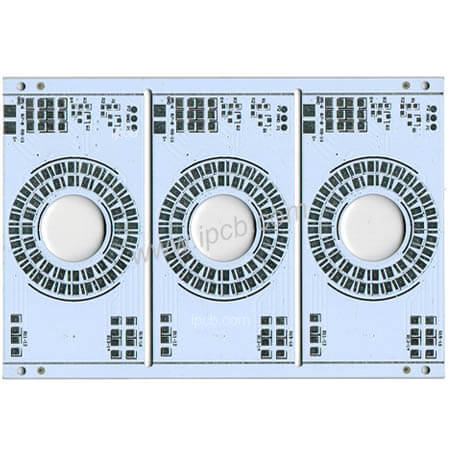

모델 : Double sided aluminum PCB

원자재 : aluminum base

층수 : 2Layers

컬리 : White/Black

완성두께 : 1.2mm

동바두께 : 1OZ

표면처리 : Lead-free HASL

Thermal Conductivity : 2.0w/m.k

스페셜 프로셔스 : The 2layer aluminum base needs to be made according to 4layer PCB

응용영역 : High end LED desk lamp

알루미늄 PCB는 금속기 PCB의 일종으로 열을 잘 방출하는 기능을 가지고 있다.일반적으로 단면 알루미늄PCB는 3층으로 구성되어 있는데 그것이 바로 회로층, 개전층과 알루미늄 기층이다.반면에 양면 알루미늄 PCB의 구조는 더욱 복잡하다. 회로층, 개전층, 알루미늄 기층, 개전층과 회로층으로 구성된다.알루미늄기 알루미늄판 재료는 열전도 계수가 높아 드릴 구멍, 펀치, 절단 등 일반적인 가공 방법에 적합하다.알루미늄판의 첨가로 알루미늄기 PCB는 우수한 열전도성을 가지게 되었고 단열 매전층은 고강도의 전기 절연 성능을 제공한다.표면에 PCB에 설치된 부품은 열을 발생시키고 열량은 개전층을 통해 알루미늄기로 전달되며 열량은 알루미늄 기층을 통해 전달되어 부품의 열을 분산시킨다.그러나 알루미늄의 전도성 때문에 층간 상호 연결 성능을 실현할 수 없기 때문에 알루미늄기 PCB의 응용도 제한을 받았다.

기존의 양면 알루미늄 PCB는 전통적인 수지로 큰 구멍을 채워 층간 상호 연결을 실현한다.그러나 단점도 많다. 우선, 전통적인 수지는 큰 구멍을 채우면 기포가 생기기 쉽고 고온에서는 균열이 생기기 쉬워 생산률이 낮다.그 다음으로 전통적인 에폭시 수지의 열전도 계수는 0.2W/(m.k)에 불과하기 때문에 알루미늄 기판의 열전도 요구를 점점 만족시키지 못한다. 이런 방법으로 생산된 알루미늄 기 PCB의 열전도 계수는공위 산열 계수와 층간 산열 계수가 다르기 때문에 제품의 품질 요구를 만족시킬 수 없다.

Double sided aluminum PCB 일반적으로 회로층, 절연층, 알루미늄 기층, 절연층과 회로층으로 구성된다.그것은 양호한 열 분산 기능을 가진 금속 PCB 회로판이다.이런 PCB판의 양측에는 모두 접선이 있지만 양측의 접선을 사용하려면 반드시 양측 사이에 적당한 접선 연결이 있어야 한다.

1、 PCB circuit layer on double sided aluminum substrate

회로층은 구리로 전기를 전도한다.

2、 PCB insulation layer on double sided aluminum substrate

단열층은 단열재로 만들어지는데, 이는 LED에서 발생하는 열이 알루미늄판으로 빠르게 전달될 수 있는지에 따라 단열재의 열저항에 따라 달라진다.

3、 Double sided aluminum PCB aluminum base

알루미늄 기좌의 기능은 단열재의 열을 다시 회로층으로 전달하는 것이고, 또 다른 기능은 설치하는 것이다.

Is the thermal conductivity of aluminum substrate better related to the thickness of aluminum plate?

사실은 그렇지 않다.알루미늄 기판의 열전도 계수를 높이려면 단열재의 성능을 높이고 단열재의 열저항을 낮추는 것이 관건이다.절연 재료의 열저항을 낮추는 것은 결코 간단한 일이 아니다. 그것은 재료 성분과 제조 공정의 영향을 받을 것이다.

도공은 PCB판에 금속을 채우거나 칠한 작은 구멍으로 양쪽을 도선으로 연결할 수 있다.양면 알루미늄 기판 PCB의 면적은 단면 알루미늄 기판 PCB의 두 배이기 때문에 양면 알루미늄 기판 PCB는 단면 알루미늄 기판 PCB의 배선이 교차하는 어려움을 해결했다(다른 쪽으로 통하는 통공).따라서 단일 알루미늄 PCB보다 복잡한 회로에 더 적합하다.

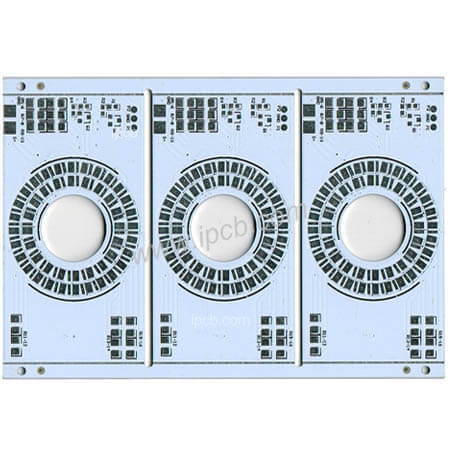

모델 : Double sided aluminum PCB

원자재 : aluminum base

층수 : 2Layers

컬리 : White/Black

완성두께 : 1.2mm

동바두께 : 1OZ

표면처리 : Lead-free HASL

Thermal Conductivity : 2.0w/m.k

스페셜 프로셔스 : The 2layer aluminum base needs to be made according to 4layer PCB

응용영역 : High end LED desk lamp

pcb 기술 문제에 대해 ipcb 지식이 풍부한 지원 팀은 여기서 모든 단계를 도울 것입니다.여기에서 pcb 견적을 요청할 수도 있습니다. 연락 주세요: E-mail sales@ipcb.com

우리는 신속하게 대답할 것이다.