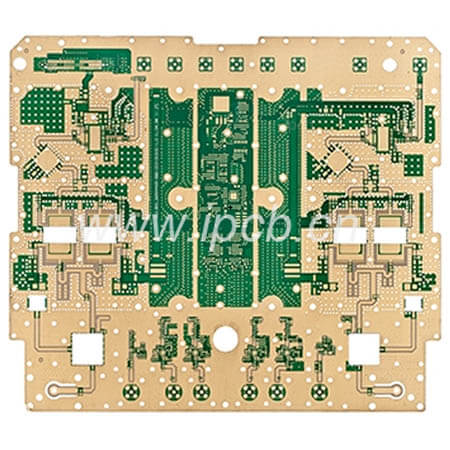

모델 :Ro4350B Ceramic Hybrid High Frequency PCB

원자재:Rogers RO4350B+FR4 Mixing Press

층수 :4L

D K :3.48

완성두께 :1.0MM

동박두께 :1OZ

Dielectric Thickness :0.762mm

Thermal Conductivity :0.69w/m.k

Flammability :V-0

표면처리:Immersion Gold

어플리케이션:Radio Frequency,Microwave Antenna

Company introduction

iPcb.com사는 중국에서 주파수 PCB 제조에 종사한 지 17년의 역사를 가지고 있다.우리는 적당한 주파수 재료가 회로판의 성능에 얼마나 큰 영향을 미칠지 안다.주파수 마이크로웨이브 등급, 작업 주파수, 작업 온도 범위, 전류와 전압 등 파라미터는 적합한 고주파 PCB 제조 재료를 선택할 때 매우 중요하다.이러한 무선 PCB 재료에 대해 숙지하는 것이 우리의 업무 중 하나입니다. 아래의 재료 목록을 보십시오.우리는 빠른 납품을 확보하기 위해 충분한 재고품을 가지고 있다.우리는 제품의 품질에 대한 믿음이 경험이 풍부한 엔지니어/생산팀에서 나온다. 그들은 우리의 품질보증부서와 밀접하게 협력하여 합격한 제품을 제공한다. 우리는 고객으로부터 큰 성공을 거둘 줄은 생각하지 못했지만 점점 더 많은 중복 주문이 그들의 만족을 나타냈다.품질은 우리 회사의 핵심 가치입니다. 우리는 품질이 장기적인 업무에 대한 중요성을 알고 있습니다. 우리 고객들이 지난 17년 동안 우리와 함께 우리의 능력과 기술 분야를 개발/개선해 주셔서 감사합니다.

RF/Microwave PCB material:

Rogers RO4350B / RO3003 / RO4003 / RO3006 / RT/Duroid 5880 / RT5870 and etc.

Arlon / Isola / Taconic / PTFE F4BM / Teflon material also shouldn’t be forgotten.

Hybrid PCB material (Mixed dielectric / Laminate)

Rogers RO4350B + FR4 / RO4350B + IT180 / RO4003C + FR4 / RO3010 + FR4 / RO3003 + FR4 / RO3010 + FR4 etc.

Radio Frequency (RF) microwave PCB application

RF Microwaves PCBs (printed circuit board) are used in various of fields, Such as Consumer Electronics / Military/Space / High power / Medical / Automotive / Industrial ect.

Surface finishing: OSP / ENIG / HASL LF / Plated gold / flash gold / Immersion Tin / Immersion silver / Electrolytic gold

Capacity: Golden finger / Heavy copper / Blind buried via / impendance control / filled with resion / carbon ink / backdrill / countersink / depth drilling / half plated hole / pressfit hole / peelable blue mask / peelable solderstop / thick copper / oversize

Material: Rogers RO4350B / RO3003 / RO4003 / RO3006 / RT/Duroid 5880 / RT5870 and Arlon / Isola / Taconic / PTFE F4BM / Teflon material etc.

Layer: 2L 4L 6L 8L 10L 12L 14L 16L 18L 20L 22L 24L 26L 28L 30L

Dielectric Constant (DK): 2.20 / 2.55 / 3.00 / 3.38 / 3.48 / 3.50 / 3.6 / 6.15 / 10.2

어플리케이션: Consumer Electronics / Military/Space / Antenna & Communications System / High Power / Medical / Automotive / Industrial / Handheld device cellular / Wifi Antenna / Telematics and infotainment / Wifi/Computing/Radar/Power Amplifiers

모델 :Ro4350B Ceramic Hybrid High Frequency PCB

원자재:Rogers RO4350B+FR4 Mixing Press

층수 :4L

D K :3.48

완성두께 :1.0MM

동박두께 :1OZ

Dielectric Thickness :0.762mm

Thermal Conductivity :0.69w/m.k

Flammability :V-0

표면처리:Immersion Gold

어플리케이션:Radio Frequency,Microwave Antenna

pcb 기술 문제에 대해 ipcb 지식이 풍부한 지원 팀은 여기서 모든 단계를 도울 것입니다.여기에서 pcb 견적을 요청할 수도 있습니다. 연락 주세요: E-mail sales@ipcb.com

우리는 신속하게 대답할 것이다.